|

|

|

|

Home →

Survival →

Clothing

Birch Bark Shoes

by

Allan "Bow" Beauchamp |

| |

| In the bush, I have found there are often times

when our survival training has gotten us out of a bad situation

and back on the brighter side of things. I have not found a

lot of emphasis on the ability to establish some form of

footwear, whether on a temporary or more permanent solution to

the problem.

In the upcoming fabrication, we will discuss a temporary

system and a permanent option.

My preference is to refer to survival concepts as options, as I

feel there is not one right answer to any problem, but many, or

a better option.

So first off, what will cause an individual in the bush to

find themselves without footwear? Listed below you will find

some circumstances that I have personally come to know as causes

for such a situation, and a solution I sought to better my

circumstances.

When venturing across a frozen lake, sometimes in the process

you will go through the ice and while trying to return to the

ice surface or shore, you might lose one or both boots, thus

leaving you without footwear.

You may be canoeing down a set of rapids with boots in the

bottom of the canoe or perhaps placed loosely on your feet, and

after an upset you emerge to find your canoe, gear, or footwear

going downriver doing the natural navigational thing. Also, when

traveling in the bush, you might stop at a lake and enjoy the

welcomed cool, wet water on a hot day, only to return to find

some small animal has run off with your salty-tasting footwear.

These examples and many more will, without a doubt, leave you

without footwear.

So, as individuals who like to spend vast amounts of time in

the bush, we must ensure our mobility, because any aspect of

bush living requires the individual to have some form of

mobility.

In this writing I have outlined some options for an

individual faced with this situation.

This article I call "Birch Bark Shoes." Practicing and

understanding this technique will give you a greater awareness

as to the versatility of nature's materials. If we take the time

to understand what is available and know what options we are

trying to accomplish, we will make it.

I have found from personal experiences, being in the Northern

Bush and experiencing the wonders of nature in all four seasons,

that nature will provide all that we need, if we take the time

to listen.

My hope is, with this information, one never has to be in a

predicament where they have to endure some of nature's harshest

climates without footwear.

I once tracked an individual lost in Northern Ontario. In the

early stages of disorientation this person had lost his shoes in

some mud pit prior to going deeper in the bush.

While tracking this individual for days, it had become

apparent to myself in the early stages that this individual was

having extreme difficulty, wandering aimlessly about without

footwear. With nature's trails and the soil releases, I came to

realize, this would become too great an obstacle for this

individual to overcome in a short period of time.

Finally, when this had become an impossible task and this

individual could venture no more (thus limiting his options for

survival), this was the end of the trail and hope for any

options. There was another instance, when I had someone call me

and ask if I would be willing to take a group into the bush.

Once in the bush, I asked everyone to remove their footwear

to see who would have an option to allow them to proceed.

I have found that many people do not usually calculate this

in to their plan of options when going into the bush, or have

come to know of some options. So what are our options?

Without an immediate solution to our being without footwear,

one must find something on a temporary basis to protect our

feet, as anyone can attest to at some time in their life, when

suddenly stepping barefoot on sharp rocks or harsh substances.

In a bush situation this is not a place to be barefoot or in

sock feet, as this will only lead to injury, pain and infection.

And if one should end up in such a situation, the rest of our

options are virtually impossible to perform, as most require

some form of mobility.

Anything temporary is just that -- temporary. But, it will

afford you the time and protection needed to stabilize your

crisis situation.

In nature, this temporary footwear task can be accomplished

by looking around the area, first for a soft dry protective

layer to go against the foot. This will give you comfort and

distance from the ground.

Any soft items such as windblown grasses, cattail down, a

compressed hive, dry moss leaves, etc., will soften and protect

the foot. Secondly, for the outer layer and a means of engulfing

the foot, this is accomplished with sheets of birch bark, a slab

of willow bark, a woven reed or birch layered mats, any firm

encompassing material that is durable for a short time solution.

To keep these protective layers securely on the foot, any

lashing items will suffice. This can come from a belt, string,

duct tape or even a roller bandage. Maybe yarn from your sweater

woven into cordage, a spruce root, making birch bark cord and

many more options will give the securing needed.

At such time as your situation has stabilized, and you now

have the opportunity to establish more protective systems, this

is a good opportunity to start the fabrication of a permanent

footwear option.

Usually most individuals at this stage in their situation

seem to have lots of time. This system of constructing footwear

will allow you to maximize this time and will assist in keeping

the mind agile, but give a great sense of accomplishment when

completed.

From this technique you will have many ideas begin to form in

your mind and other comforts you can obtain in your situation,

such as birch bark sleeping bags to fill with cattail down to

sleep in instead of on the ground, birch back pack sacks to

allow you to transport forded supplies and many more ideas we

will cover later. |

| |

|

These birch bark

shoes, when constructed in the fashion we will

describe, give the best comfort and mobility, as

bush ground is very uneven and slippery in most

cases. The shoe to be constructed is naturally made

of birch bark from the white birch tree. This tree

is classified as a hard wood and is plentiful and

very visible in most areas. See photo 1.

The white birch tree is a very versatile tree, and I

am sure will offer many options to an individual

faced with unforeseen circumstances. Some of its

versatile uses include water, fuel, navigation,

shelter, cooking and medicinal to name a few.

When a stand of white birch is found, use

whatever cutting implement you have at the time. Cut

a strip vertical down the tree and pry back the

layers of bark.

In the spring the bark will release from the tree

easier, being your optimum, but even if it is not

spring, this can still be accomplished. The back for

the fabrication of the shoes in the photos was

acquired in late November. This will ensure the

reader that late season bark will also serve our

purpose.

|

|

|

With the vertical

strip cut, there will be the outer whitish layer and

the "leathery" brownish layer. The best I find for

fabrication of the shoe is the brownish layer, but

as the photos depict, I have also crafted with the

outer layer. From photo 2 you can see the

difference between the tree's exterior and the

interior back layers. Provide yourself with a good

number of these bark sheets. The longer the vertical

cut and the bigger diameter of tree will provide you

with a bigger sheet to take your material from. |

|

|

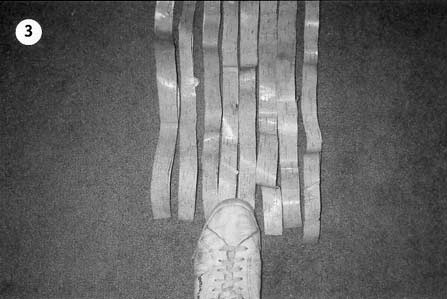

In photo 3 I

have taken these sheets and separated the layers of

bark, then cut strips from the bark at approximately

three quarters of an inch wide and approximately

three feet long.

Whether the strips are cut vertically across the

bark sheet or horizontally across the sheet will be

your preference. Cut a test strip from each

direction and pull until breakage occurs. This not

only gives you your strength of the strips, but a

feel for how tight to pull the strips when

fabricating the shoes.

|

|

| With approximately sixty-five strips of 3/4"

wide and 3 foot long, I lay the strips as shown in photo 3

to get a gauge for how wide to lay them. Use your foot as I have

done with the shoe in the photo, or draw an outline in the dirt

of your foot's dimensions. Lay approximately eight or nine

strips lengthwise on the ground, and this should accomplish this

task.

When cutting birch strips from a round tree and trying to lay

them flat on the ground, they will seem springy.

So to reduce some of this springy memory, soak these strips

in water if available. This should assist greatly with the

springiness and also later when the weaving process has begun.

You will see that the wet slick strips not only slide easier but

form to mold better. |

|

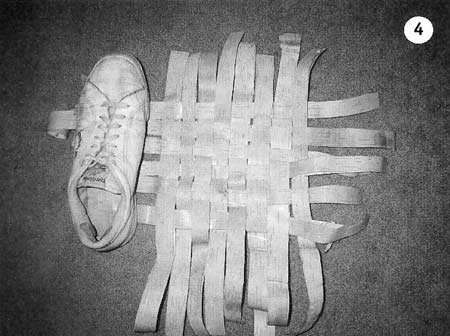

In photo 4 you

can see the weaving process begin with strips laid

lengthwise. Now put some strips width-ways, starting

at the midpoint of the length strips and coming

across the length strips. Take one strip at one side

and go under a length strip first, then continue on

to the strip laying beside it and go over that

strip. Then proceed to the next strip and under

again. Continue this process until you have achieved

the look of the matting in photo 4. Snug the

strips up now to remat any gaps and to ensure a

solid weave. |

|

|

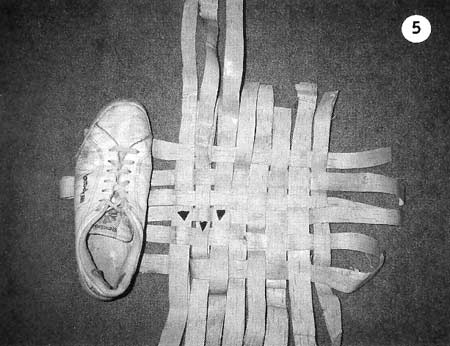

Some ideas, as I

mentioned earlier, will start to develop in your

mind for how to use this technique for other

comforts: possibly shelter walls, a rain catcher, a

sun shade, etc. Photo 5 shows a process of

how to add length to the strips to allow you to make

your matting longer or wider. I have cut the ends

of my strips to a point. This facilitates easier

weaving of over and under.

Add enough strips length-ways and width-ways to

your mat that will give you the size desired.

If you go wider or longer at this point, it will

greatly assist your fabrication later on as you will

see in the photos.

|

|

| The matting that is being constructed at this

point forms the sole of your footwear, and the added length of

strips that are put in, add to your thickness. |

|

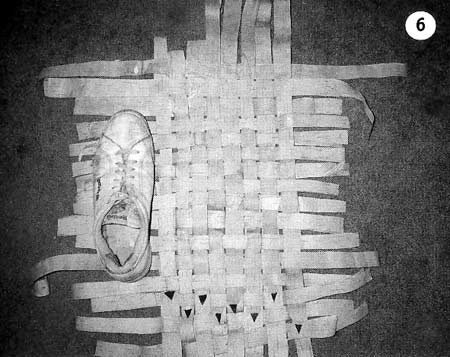

So one stage

complements the other. In photo 6, this is

the length and width at this point. I find it

beneficial for the length at this stage to be

longer. This will facilitate much easier curvature

of the toe section once the front of the shoe is

pulled over. |

|

|

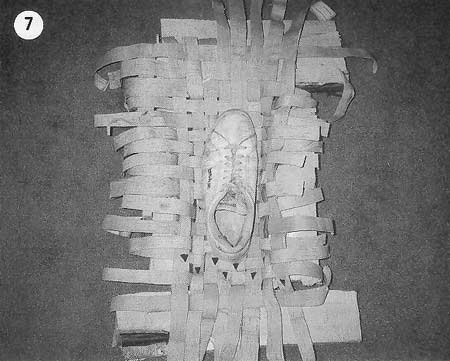

Photo 7 gives

you the idea now of the benefits of the matting

being extended beyond your initial dimensions. If

you feel that more matting is needed, this is a good

opportunity to add to your mat. If sufficient

then, place your foot onto the mat and find

something to assist in forcing up the sides. This is

only necessary if you feel you cannot hold the

strips in one hand and weave with the other.

In the photo, I have used some pieces of willow

that are soon to become my fireboards.

Look for a couple of logs or stones in the bush

or dig in the sand a small depression, a little

wider than the dimensions of your foot you drew

earlier. |

|

| With time and practice, you will find fewer

items will be needed for assistance. In photo 7 the

heel is placed where the overlapped strips stopped. Push down on

the shoe, or push your foot onto this matting and force the

sides up to start to mold your matting into your foot

dimensions.

If the shoe's dimensions were out of proportion to your foot,

this would only facilitate a sloppy shoe and would not be as

effective for mobility.

With the toe section being woven past the tip of the foot,

now the front section is rolled over towards the tongue of the

foot. Thus, the task of holding and weaving strips is much

easier in the forming of the top section. |

|

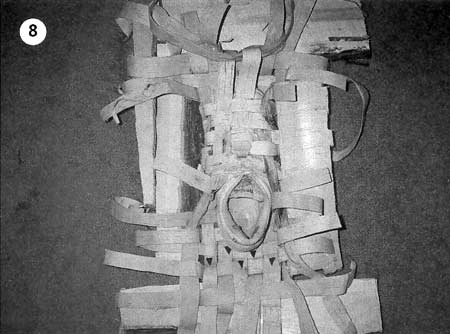

Photo 8 shows

how this toe section is pulled up towards the top of

the tongue, and this edge now becomes the starting

rim where your foot will ultimately slide into.

Now that you have the woven mat placed against the

tongue section of the shoe, use the width strips to

join the sides of the shoe to the top mat section.

While still applying the over and under process,

at this stage of adding layer upon layer, the wet

strips give some advantage with their slickness. As

the stiffness of the shoe becomes apparent, so does

the tightness in between the weaves. |

|

| To help send the strips through this tightness,

the cut, arrowed ends assist in weaving. When pulling these

strips through, snug them up and keep the form of your foot in

mind. The tension you can apply on these strips, as you will

see, is considerable, as first seen in the test strips. This

will, no doubt, give you the idea for the cordage we mentioned

earlier.

Continue this process all around the shoe, as the front

matting has started the rim of your shoe to slide your foot

into.

To fabricate the rim for the rest of your shoe, you will see

that when pulling up the sides, a long length strip will go

right around the heel section, thus giving you the rim of your

heel section for the rest of your strips to weave into.

When you have strips that are longer than your rim, do not

cut them off. Just fold them over and weave on the inside with

the extra length. This adds layers to your shoe and stiffens the

shoe.

Now, to add layers to the inside toe section. This is a

difficult task, but if you in the first couple of photo (photo

5 & photo 6) added an extra layer or two, you now

have gained the thickness inside the shoe in that section and do

not have to do the toe section at this stage with extra length

strips. Weave these around the shoe also. |

|

In photo 9 we

see a somewhat completed formation of the shoe,

close to dimensions. At this time, it is best to

tighten up the straps and mold the matting and keep

adding layers of straps to the exterior and interior

of the shoe. The amount of layers one adds will

depend on the amount of protection they wish to

achieve. My preference is to add lots now to save

having to add lots later.

At this point in fabrication of the shoe, it

might feel somewhat "springy." This is normal. By

adding more layers and tightening the straps and

removing any gaps, soon the springiness will be

replaced by solidness. |

|

| If your first shoe is imperfect, this can be

overcome with practice and visualization. Try making a miniature

model at first, say, the size of a children's shoe. This will

assist you with forming, holding and weaving the shoe and get

the final product more quickly so you can see where you will

have some difficulties prior to forming a full-size shoe. |

|

With more strips, lots

of tension applied and all gaps reduced, your shoe

should look close to photo 10. At this

stage your shoe will easily fit inside the formed

shoe. This is the advantage of a shoe, rather than a

boot style. The shoe allows more flexibility of the

foot in negotiating the bushes and uneven ground,

where a boot style has a limited range in the

forward motion.

A low shoe doesn't offer much protection in the

shin area. This can be supplemented with a slab of

birch bark under your pant leg or wrapped around

your leg and secured with one of the means described

earlier. |

|

| The shoe at this point is still not

form-fitting enough to eliminate shoe wobble. This is achieved

with the help of cattail down, dry leaves or grasses-any dry,

soft substance that will warm the foot, compress to contour to

the foot and will not cause abrasions. |

|

In photo 11 you

now see the shoe filled with cattail down. This

substance not only warms, but contours well and

gives the foot protection on the inside against the

edges from the strips, as the strips give the foot

protection from the edges of the earth. Using a

small twig, you can force in a lot of down around

your foot and fill in the hollows around the foot,

causing a tightness to occur which will assist in

walking.

|

|

|

To add to our already

manageable shoes, I offer more options to protect

our shoe even further, as seen in photo 12.

This is a slab of willow bark, off my walls. This

will be placed on the bottom of the shoe to offer

another layer from the elements and to protect the

strips as well.

In early mornings when the dew-laden ground

becomes slick, this rough bark will give you some

lateral stability when negotiating the uneven

ground.

|

|

|

In photo 13 we

see that the attachment of this slab to our shoe

follows the process in which the shoe was

fabricated. Put as many strips as needed to tighten

the slab to the shoe to ensure the slab stays

solidly attached. With the extra strips of bark,

keep these for your journey, because as you are

mobile, the strips will wear out or tear. This is

easy to rectify as the extra strips can be woven

back into the shoe on the move.

|

|

| During your night of fabrication should you

receive a good blanket of snow and are in need of some flotation

on the snow, this can be accomplished with more bark placed to

the side of the bark, increasing the width of the shoe's

surface, or use a wider piece initially. To fully see the

advantage of your birch bark shoes, remove one shoe and travel

for awhile. Experience will be your best teacher.

Whether you prefer these shoes with the bark on or off will

entirely depend on you. I feel, if you have the advantage of

extra protection, utilize it.

Now that you have stripped the bark off the birch trees in

your area, I am confident the contrast of white exterior and

brown interior as seen in photo 2 will assist your

situation, affording you another option.

In closing, having the opportunity to go into the bush and

practice our skills, which enhances our comfort and

survivability, is an opportunity that should not be taken for

granted but respected.

Our respect should come in the form of utilizing the

material, but only that which we need to accomplish those tasks.

This way we do not rob our children's children of the

opportunity to go into the "bush."

The "bush" is the greatest teacher one could sit and listen

to.

You will learn more about natural navigating by following a

wolf, than my global positioning system (GPS) will teach you.

Nature will never steer you wrong!

Article and Photos Copyright

©

Allan "Bow" Beauchamp.

This article originally appeared in

Wilderness Way magazine,

Volume 5, Issue 1. |

| |

|

|

|

|

|

|

|