|

|

Home →

Survival →

Fire →

Fire Pistons

Model "T" Fire Piston

Article and photographs by Rob Bicevskis

Page 1 of 3

Page 1

Page 2

Page 3

|

|

*** WARNING

***

This page

contains instructions on how to make a fire piston

using "common" materials. The pressures

generated in a fire piston are very high and may be

beyond the design limits of some of the component

materials. If you try building a fire piston

according to these directions, you do so at your own

risk. I have not had any catastrophic failures

with this design, but that doesn't mean it won't or

can't happen. Please take appropriate safety

precautions.

|

|

|

|

|

|

The Wildwood

Survival website contains a few articles and references

to Fire Pistons. A number of people have

emailed me about making or buying Fire Pistons.

In some cases, the first emails were about help in

building a Fire Piston, and subsequent emails have

been about where to buy one. This is

indicative of the success rate that people have been

having in the construction phase!

(By the way, I don't sell Fire Pistons. If

you want a ready-made unit, there are people such as

Jeff Wagner and Steve Leung who have been making

Fire Pistons for a while and would be happy to sell

you one. I have one of Jeff's fire pistons.

He makes a beautiful quality product. I met

Steve Leung a number of years ago and have seen his

fire pistons in action. Check out the

web-sites that belong to either of these guys.)

A friend, Ron White, and I have been building

various types of fire pistons over the last number

of years. I have experimented with styles that

more or less required a lathe in the construction

process. Ron has played more with what can be

done with "common household materials." The

result of much of this experience is encapsulated in

this web page.

About a hundred years ago, Henry Ford said about

the Model T Ford: "I will build a motor car for the

great multitude."

Well, the Model T Fire Piston is a design for the

abo masses.

(There must be at least a hundred of us or so,

no???)

The idea of the Model T Fire Piston is that for 5

bucks and an afternoon of effort, you can build

their own fire piston. No special tools or

skill are required. Clearly this PVC based

design isn't as elegant as other

wood/plastic/bamboo/horn/bone models, but it is a

great intro to Fire Pistons and is a great platform

for experimenting. |

|

|

|

Ok, you've

read this far, and I know you're asking: "whadda I

get for 5 bucks and a few hours of my time?" Well,

I'm glad you asked.

Click on the video to the left and you will see the

Model T Fire Piston in action.

Wasn't the video neat? I hear you saying:

"yes, yes, I want to build one!" |

|

|

| Building the Model T Fire

Piston |

| |

|

|

|

O-Ring

Plunger Parts List |

Amount Needed |

|

|

|

|

3/4" CPVC End Cap |

2 |

|

3/4"-1/2"-3/4" T Fitting |

1 |

|

1.4" of 3/4" CPVC Pipe |

2 |

|

1.5" of 1/2" CPVC Pipe |

1 |

|

#6 Wood Screw 1/2" Long |

1 |

|

11" of 1/2" Hardwood Dowel |

1 |

|

Wine Bottle Cork |

1 |

|

5/16"x7/16" O-Ring |

1 |

|

|

|

|

Cylinder Parts List |

Amount Needed |

|

|

|

|

1/2" CPVC |

9" |

|

1/2" CPVC End Cap |

1 |

|

|

|

|

O-Ring Grove Jig |

Amount Needed |

|

|

|

|

1.5" of 1/2" CPVC Pipe |

2 |

|

1" of 1/2" CPVC Pipe |

1 |

|

1" of 1/2" Hardwood Dowel |

1 |

|

1/2" CPVC End Cap |

1 |

|

1/2"-1/2"-1/2" T Fitting |

1 |

|

|

|

|

Miscellaneous |

Amount Needed |

|

|

|

|

Glue for CPVC |

Dab |

|

Epoxy Glue for O-Ring Groove |

Dab |

|

Vaseline |

Dab |

|

Tinder |

Some |

|

|

Here is the parts list

for the Model T Fire Piston. All of these items

can be bought at your local hardware store.

See below for details and some construction

options. If you opt for the syringe-style gasket,

then you can substitute any 7/16" dowel for the 1/2"

dowel in the parts list. Also, you won't need

the O-ring Grove Jig parts. |

|

| |

|

| Building the cylinder |

|

While boring

an acceptable hole in a piece of wood or plastic

isn't always easy, making the cylinder from CPVC is

a trivial exercise.

Cut a 9" piece of 1/2" ID CPVC. |

|

|

When buying your "end

caps," check to see whether the ones at your local

store have a "nipple" inside. If

the nipple is there, it will press against the

plunger, or against the tinder in the end of the

plunger. So, either buy end caps such as the

one on the left that don't have the nipple, or if

you end up with a cap such as the one on the right,

it is better to carve it out. If you have CPVC

cement, use it to seal one end cap to the end of the

cylinder. If you don't have CPVC cement, you

can also use epoxy glue. You will need epoxy glue

later in this project, so if you need to buy

adhesives, buy the epoxy. It is a waste to buy

a whole can of CPVC cement since so little is

required.

Using sandpaper, or a knife, smooth out the

inside edge of the opening of the cylinder.

This will allow the plunger to be inserted more

easily.

There, the cylinder is done!

|

|

|

| Building the Plunger - The

Handle |

|

This is what

the plunger looks like when it is finished.

The "T" handle is an ergonomic way of holding the

plunger.

It also provides storage. |

|

|

Removing one

end-cap from the handle reveals the storage area for

tinder. |

|

|

Removing the

other end-cap show where Vaseline is stored.

The Vaseline is used to lubricate the plunger

O-ring. It can also applied to cotton balls,

or other organic material and makes a great

fire-starter. |

|

|

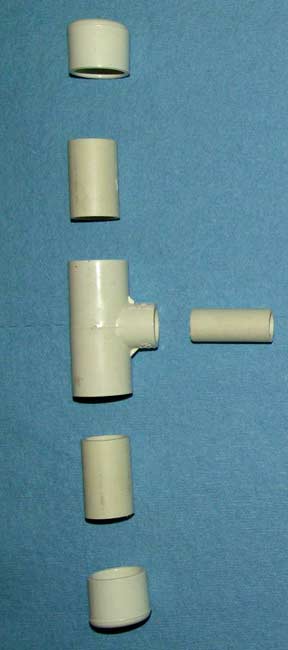

Here is an

exploded view of the top portion of the plunger.

Refer to the parts list for the lengths of the

CPVC pieces. |

|

|

The first

construction step is to cut the cork in half and

press-fit it into the 3/4"-1/2"-3/4" T Fitting.

The purpose of the cork is to separate the tinder

and lubricant compartments in an air-tight and

water-tight fashion. If you don't want to

bother with storage in the handle portion, you can

skip this step. |

|

|

This is what

things should look like with the cork inserted.

You can now cement (CPVC glue or epoxy) the two

1.4" of 3/4" CPVC Pipe pieces to the T fitting.

Also, cement the 1.5" of 1/2" CPVC Pipe to the

remaining opening on the T fitting.

|

|

|

This is what

things should look like at this point.

..... on to Page 2 |

|

|

|

Page 1

Page 2

Page 3 |

|

|

|

|