|

|

Home →

Survival →

Fire →

Fire Pistons

Model "T" Fire Piston

Article and photographs by Rob Bicevskis

Page 2 of 3

Page 1

Page 2

Page 3

|

|

Building the Plunger - The Piston- "O" Ring

Method |

|

This is the

trickiest part of the whole project - the plunger

itself. We are going to use an O-ring to

provide an air-tight seal to the cylinder.

Don't cut the wooden dowel to length at this

point. It might take a try or two to get

the O-ring fit just right. If you make a

mistake, it is a simple matter to cut off the end of

the dowel and you can try again. |

|

|

|

|

Step one is

to check whether the dowel fits inside of the 1/2"

CPVC pipe.

In theory, the inside diameter of the CPVC pipe

is about 1/2" and the outside diameter of the dowel

is 1/2" so there is a chance that the dowel might

fit.

(We all know that: "In theory, there is no

difference between theory and practice, but in

practice there is. " Source unknown.)

We don't want a tight fit. The O-ring will

provide us with an air-tight seal, not the wood.

Usually I have had to reduce the diameter of the

dowel slightly. |

|

|

A knife can

be used as a scraper to remove material quickly from

the dowel.

Try to keep the dowel round during the scraping

process.

After scraping, or if the diameter is almost

correct, smooth things off with some sand paper.

Remember, the dowel needs to slide freely. |

|

|

Now for the

gasket.

This is our goal. An O-ring seated in the

dowel a short distance from the end.

In order for the O-ring to seal properly, we need

to cut a groove into the dowel.

For this, we are going to make a jig. |

|

|

Another view

of what we need to achieve. |

|

|

This is what

the jig looks like.

It is an assembly of CPVC pieces that allows us

to cut a very controlled slot near the end of the

dowel. The knife/saw is held stationary, and

the dowel is rotated. This forms the slot.

The width of the saw should be equal to, or

slightly less than the thickness of the O-ring. |

|

|

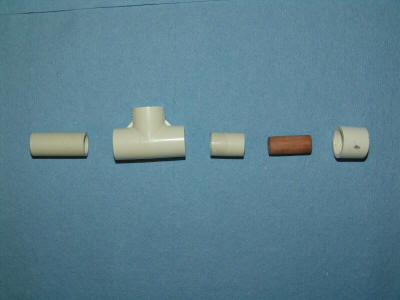

Here is an

exploded view of the jig.

Use the parts list above for dimensions of the

pieces. |

|

|

Here is a

partially assembled version of the jig. Note

the slot that has been sawn into the T-fitting.

The trick is to cut the slot just deep enough that

the knife/saw blade won't cut too deeply into the

end of the dowel. |

|

|

A top view of

the jig.

There is no need to glue the pieces together.

A press-fit should be good enough. |

|

|

We are now

ready to make the cut.

Cut a ways into the dowel, then remove it from

the jig and test for a fit into the cylinder.

This is an iterative process. Test, cut a

bit, and test again. At this point we are

going for a tight fit. |

|

|

A dental pick

is a useful tool for removing the O-ring from the

slot.

|

|

|

When dowel

with O-ring can be forced in the cylinder, it's time

to smooth out the slot with some sandpaper.

One technique to to fold some sandpaper over a piece

of string It is important not to remove too

much material during the sanding process. |

|

|

A folded

piece of sandpaper can also be used.

Sand and retry the fit in the cylinder.

Keep sanding until the dowel + O-ring starts to

slide freely in the cylinder. You should be

able to generate a distinctive "pop" sound as you

remove the plunger from the cylinder. |

|

|

Almost

done....

Mix up some 5 minute epoxy and slather it all

over the end of the dowel. This will seal the

wood. Now roll the O-ring into its slot and

wipe off the all of the exposed, excess epoxy.

Slide the plunger into the cylinder and let the

epoxy set. |

|

|

To get a feel

for how much friction there should be on the

plunger, watch this video: Bounce

Video.

Notice how easy it is to depress the plunger, and

how far back it bounces from the air pressure.

If there is too much friction, one won't be able to

generate enough speed to get a high enough pressure

to light the tinder. This is the biggest

factor in the success of the fire piston. |

|

|

Now drill a

hole into the end of the plunger. Using a 1/4"

bit and going about 3/8" deep is a good starting

point. Since this design gives some much

volume and compression, the hole isn't all that

critical.

Note that this hole already has some tinder

fungus loaded into it. |

|

|

Here are some

ideas for non-traditional holes. A hole that

goes across the dowel makes for easier removal of

the tinder. This particular plunger has a hole

in both dimensions. The thought here was that

the hole in the end would better expose the tinder

to the high pressure/temperature air, and the hole

in the side would make it easy to pop out the

tinder. This worked out well. |

|

|

Now we cut

the dowel to size, and insert it into the T handle.

The length of the dowel should be such that it

"just" touches the bottom of the cylinder. Any

air-space left over is a bad thing since it reduces

the possible maximum pressure. If the dowel is

too long, it will bottom out - which is OK, but puts

greater stresses on the whole assembly. A

perfect fit isn't all that hard to do. ..... on

to Page 3 |

|

|

|

Page 1

Page 2

Page 3 |

|

|

|

|